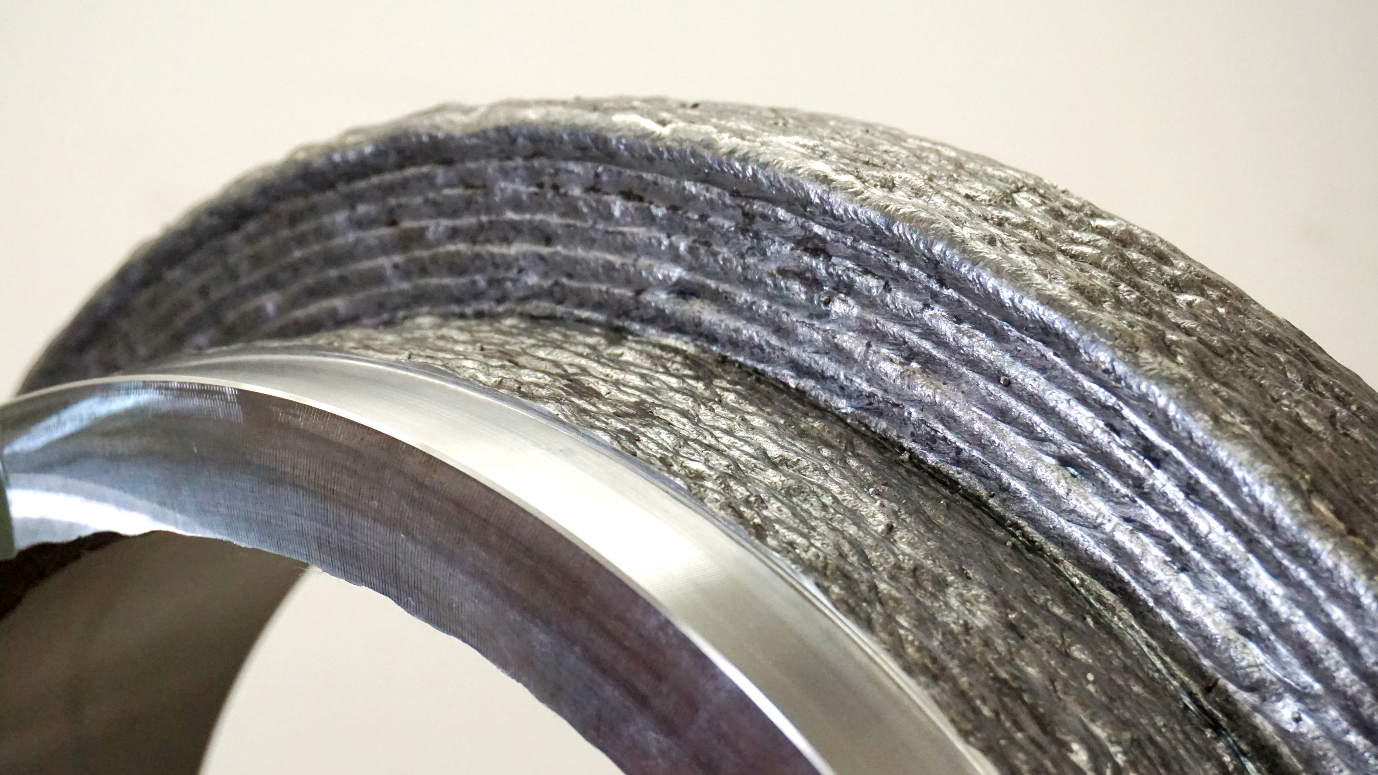

With an inner diameter of 400 mm and a finished weight of approx. 85 kg, ADMOS presents the first 3D-printed composite slide bearing at the Hannover Messe 2017. The special feature of the 100 % generatively manufactured part is the fact that, in addition to the actual production, two different additive manufacturing technologies are used simultaneously. The steel body was welded using an electric arc-based metal printing process. After machining, the part was coated with a bearing metal by laser cladding. The created additive hybrid represents an intelligent combination of two additive production technologies and enables the well-directed exploitation of the respective process advantages.

| printed weight: | 90 kg |

| build-up rate: | 400 cm³/h |

| print time: | 30 h |

After the mechanical processing, the base body of steel was coated by a laser cladding process. The powdered bearing metal is feeded to the component surface via a nozzle and it is melted completely by the energy of the laser beam. The sliding surface is applied layerwise and has a firmly bonding connection with the base material. The advantage of this powder-based process is the possibility to process a wide range of materials, such as the classic tin-based and copper-based bearing metals.

| cladded weight: | 7 kg |

| layer thickness: | 4 mm |

| print time: | 2 h |

Particularly with regard to the fast availability of components, there is a number of possibilities compared to the conventional production process:

In addition, the reduction of the used materials in the production process can save considerable amounts of raw materials.

Fields marked with an * are required