As a traditional plain bearing manufacturer, ADMOS mainly produces composite plain bearings for machine and plant engineering. Laser cladding has been developed as an alternative to the existing casting processes. These is a so-called generative process for coating surfaces on a base body of steel or high strength copper alloy.

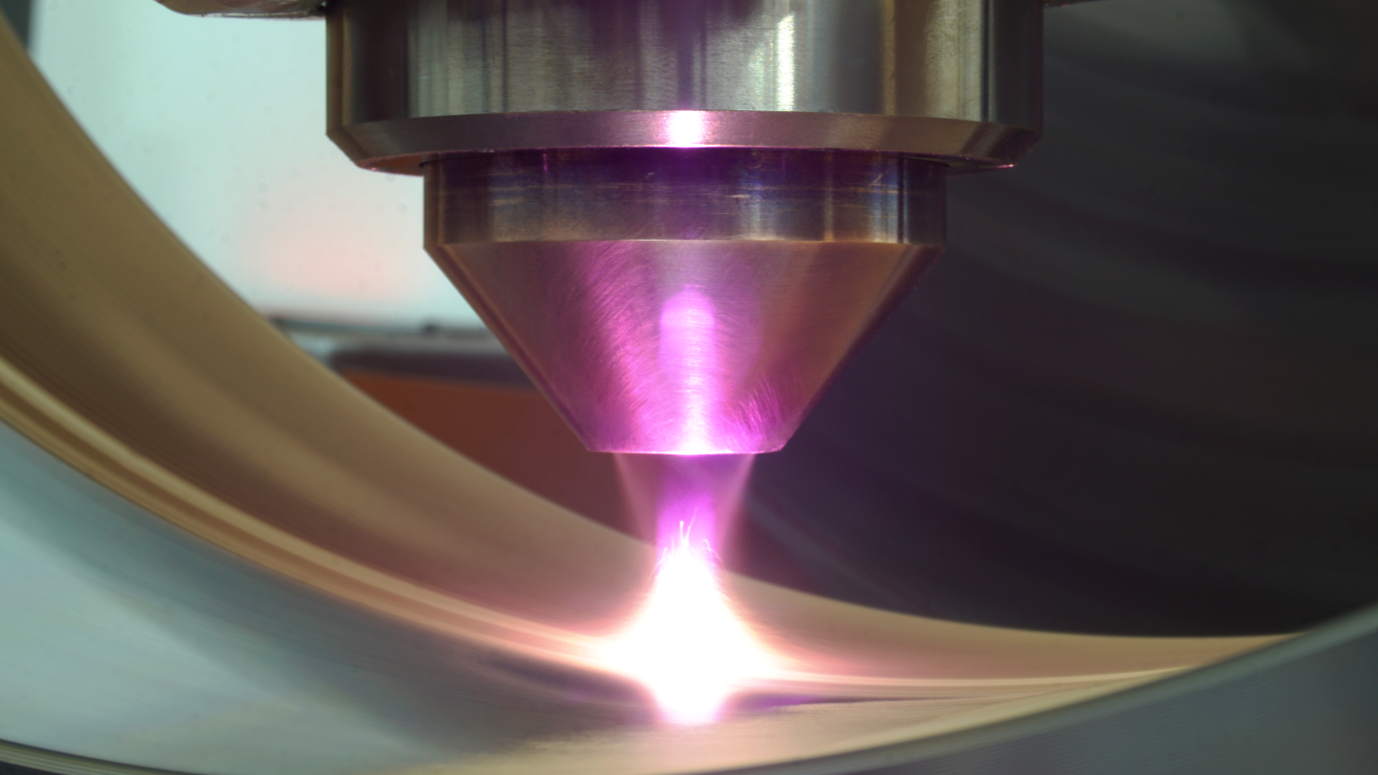

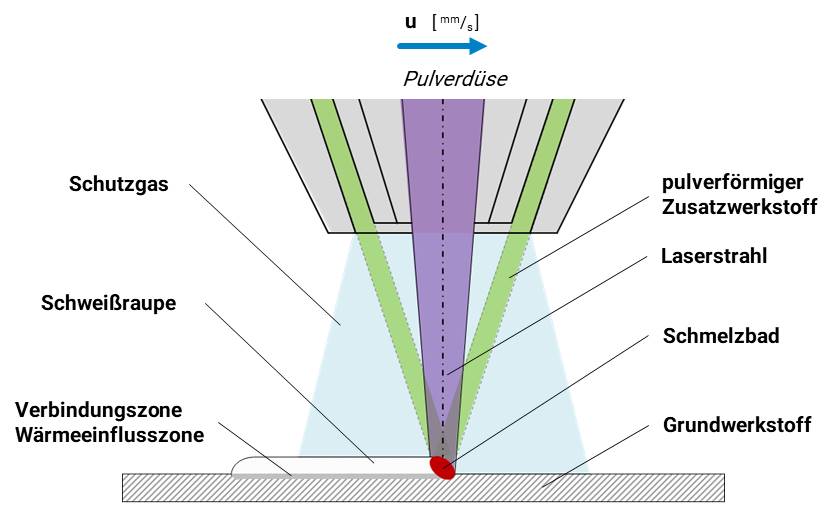

A laser beam, which is focused on the component surface via optical components, serves as the energy source. As a result of the continuous feeding of the powdered bearing material, a local molten bath forms on the component surface. Through the solidification of that weld pool, a firmly bond is formed with the base material. Any layer thickness can be generated by a track or layer-wise welding.

For tin-based bearing materials, the welding process was qualified by an independent institute in the course of a welding procedure test in accordance toDIN EN ISO 15614-7.

The system concept allows a maximum flexibility with regard to the geometries who can be coated. A multi-axis industrial robot serves as a carrier system for the processing optics and allows a free positioning of these anywhere in the room. At the same time, a flexible clamping device is provided for handling the workpiece. For the use of all degrees of freedom and for the building of even the most complex motion paths, a offline programming with a powerful 3D-CAM system is used.

ADMOS is able to process all common bearing materials by welding. The method has a number of substantial advantages over the traditional casting process.

Fields marked with an * are required